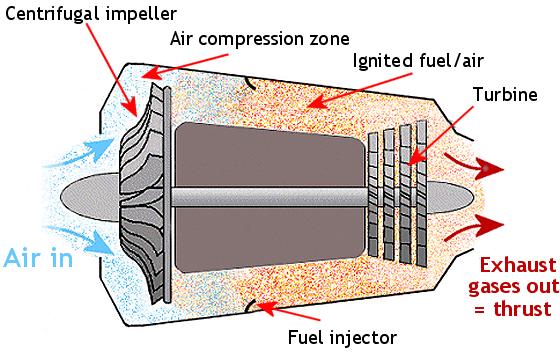

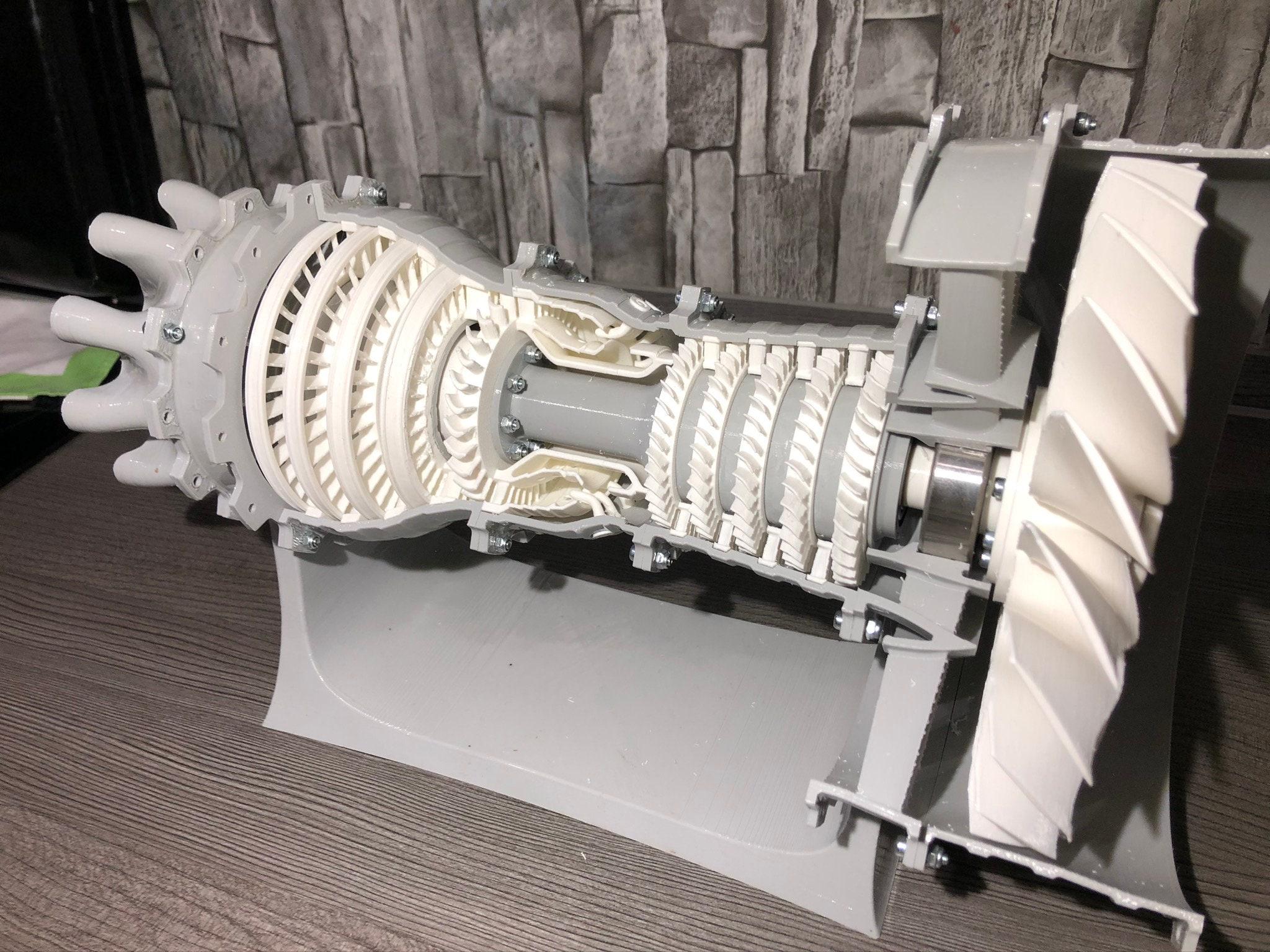

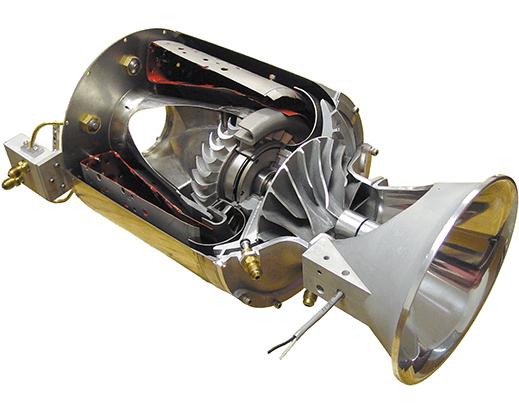

A working model jet engine is a miniature version of a real jet engine that mimics the same design and performance. The model is typically made for educational purposes and is used to teach students about the inner workings of jet engines. These models can be used by aviation enthusiasts and engineering students to learn about the engineering principles of jet engines and their basic operation. The construction of a working model jet engine mainly involves designing and assembling individual parts. The model engine consists of components such as a compressor, combustor, and turbine. Each component is designed and built to fit into the model engine. The design process is often guided by the real-world jet engine blueprints, and it requires careful attention to detail.

The construction of a working model jet engine mainly involves designing and assembling individual parts. The model engine consists of components such as a compressor, combustor, and turbine. Each component is designed and built to fit into the model engine. The design process is often guided by the real-world jet engine blueprints, and it requires careful attention to detail. Some points that should be kept in mind during the construction process include:

Model jet engines can be found through various online stores and websites that cater to aviation enthusiasts and engineering students. These websites typically provide detailed instructions on how to build the model jet engine. Additionally, they also offer kits of the various components required for building the model. These kits include everything from the engine core to the fuel lines and control systems. By purchasing a kit, learners and enthusiasts can save time and money by having all the necessary components pre-packaged.

Brand Anchor Texts:

Some safety standards that should be followed during the construction of a model jet engine include wearing appropriate personal protective equipment, using high-quality materials, ensuring proper fuel and air flow, testing the engine in a safe and controlled environment, and seeking expert guidance if necessary.

To power up the working model jet engine, it requires the use of fuel and electricity. The model engine is often fuelled with kerosene or methanol, and it requires an external power source to operate the electric motor that drives the compressor. The turbine is used to generate the power required to turn the compressor and produce thrust that propels the engine forward. Some interesting facts about model jet engines include:

| Fuel type | Advantages | Disadvantages |

|---|---|---|

| Kerosene | Efficient burn, readily available | Produces some smoke, requires regular maintenance |

| Methanol | Produces high power, efficient burn | Requires more frequent maintenance, not readily available |

Model jet engines can be purchased from various online stores or aviation websites. Manufacturers such as JetCat and Wren turbines offer a range of model jet engines, from small 20N engines to powerful 400N engines. These models are designed to provide optimal performance and efficiency, making them ideal for powering model airplanes and helicopters. In addition, many online stores provide detailed instructions on how to power up and operate the model engines, as well as how to maintain them to ensure they last for a long time.

Popular model jet engine manufacturers include JetCat, KingTech, and Wren Turbines. These engines can be purchased directly from the manufacturers’ websites or from various hobby retailers.

Model jet engines are typically single-spool designs, which means that they have only one compressor and turbine rotor. However, some model jet engines can have multiple spools that are more complex and powerful with a higher level of precision and reliability. The spool design enables the engine to have a higher thrust-to-weight ratio, which makes it ideal for powering working model jet engine. Some of the advantages of using multi-spool jet engines include:

Multiple companies offer both single and multi-spool model jet engines, including JetCat and Wren turbines. These models come in different sizes and power output to accommodate various needs, from small-scale hobbyists to professional-grade remote control models used in aerial photography and drone racing. Engineering enthusiasts can also opt to build their model jet engines from scratch using a kit and blueprint. This option is ideal for learners looking to deep dive into the engineering principles behind jet engines.

There are several advantages of using multi-spool jet engines in model planes, such as increased power and efficiency, smoother operation, and better control during flight.

One of the most critical aspects of designing and building a working model jet engine is ensuring that it operates safely. The model engines should be properly tested to avoid accidents during operation. The safety measures that should be taken into consideration include:

Professionals should be consulted to guide in the testing and unit setup to ensure the safety of all users. Several online resources provide the necessary safety guidelines for building and operating model jet engines, including websites such as RC Groups and Academy of Model Aeronautics (AMA). The AMA also provides guidelines for the safe flying of the model aircraft and remote control technology needed to operate the engine.

Wear protective gloves and clothing, use proper fuel handling equipment, store fuel in an approved container, and operate in a well-ventilated area.

The working model jet engine technology continues to evolve as new innovations are discovered. There are new model jet engine designs that are more efficient and powerful while also being easier to build. Some of these new innovations and designs include:

Enthusiasts can find online forums dedicated to model jet engines, such as RCU (Radio Control Universe) and RC Groups, to stay updated with the latest developments in the industry. Additionally, many online stores such as HobbyKing and Tower Hobbies provide the necessary parts and components needed for building a working model jet engine. With regular updates and new products coming to the market, enthusiasts can enjoy the thrill of building and operating new and improved model jet engines.

Some online forums and stores dedicated to model jet engines are RCGroups, Chief Aircraft, and Dreamworks Model Products.

In conclusion, working model jet engines offer an excellent opportunity for aviation enthusiasts and learners to explore the science behind jet engines. With their intricate designs and complex operation principles, model jet engines provide a fascinating insight into the inner workings of aircraft propulsion. The building process not only requires precision and attention to detail but also helps enhance one’s understanding of various engineering principles. Moreover, the continuous evolution of model jet engine technology provides enthusiasts with an exciting opportunity to stay up-to-date with the latest developments and innovations in the industry.

From 3D printing technology to the latest electronic control units, new technologies are continually pushing the envelope of what is possible with model jet engines. Enthusiasts can easily purchase the parts and components they need to construct and operate their model engines from specialized hobby stores and online forums. In addition to the technical aspects, model jet engines are a great hobby to foster community spirit as enthusiasts share their knowledge and creations publicly.

As new technologies emerge and enthusiasts share their findings, the working model jet engine is a hobby that will continue to intrigue learners and aviation enthusiasts. Whether for scientific or recreational purposes, this technology offers a unique perspective into the science of propulsion engines, making it a worthwhile endeavor for anyone interested in the field of aeronautics or engineering.